New tech can detect fingerprints on bullets where none could be found previously

Irish chemists have revived fingerprints from brass bullet casings that were scorched, stored for more than a year, and long considered unrecoverable. In controlled tests, they recovered ridge and pore details that standard forensic methods cannot reach.

The breakthrough comes from Maynooth University, where researchers used a tiny electrical push and a mild chemical bath to make hidden patterns develop on their own. Instead of scrubbing or etching a casing, the process lets electrochemistry reveal what heat and firing usually erase.

Heat erases fragile fingerprints

A latent fingerprint – an invisible pattern of skin oils and sweat left by touch – is fragile and easy to erase. The heat, gas, and friction of a gunshot can strip or smear that trace in milliseconds.

Gun barrels can reach very high internal temperatures during use, and many systems manage to stay under about 800°C to protect steel parts. Those conditions help explain why bullet casings often look spotless to the naked eye.

The university announcement noted that researchers have long viewed the recovery of fingerprints from fired bullets as a major challenge.

It explained that the heat involved in firing usually destroys biological traces on the casing, yet the team’s method was able to bring out ridge details that standard approaches cannot reveal.

Fingerprints reappearing on bullets

At the heart of the approach is electrodeposition, a process that uses electricity to lay a thin material onto a surface. Here, the fingerprint itself acts like a stencil that blocks where the material can land.

A low, steady voltage turns the casing into part of a simple circuit. A potentiostat – a device that holds that voltage constant – controls the reactions so the coating grows only in the tiny gaps between fingerprint ridges.

The coating mixture includes a dye related to phenothiazine, a ring-shaped molecule that readily shifts electrons. That behavior helps the material deposit cleanly and produce crisp contrast without harsh reagents.

Clear fingerprint detail after extremes

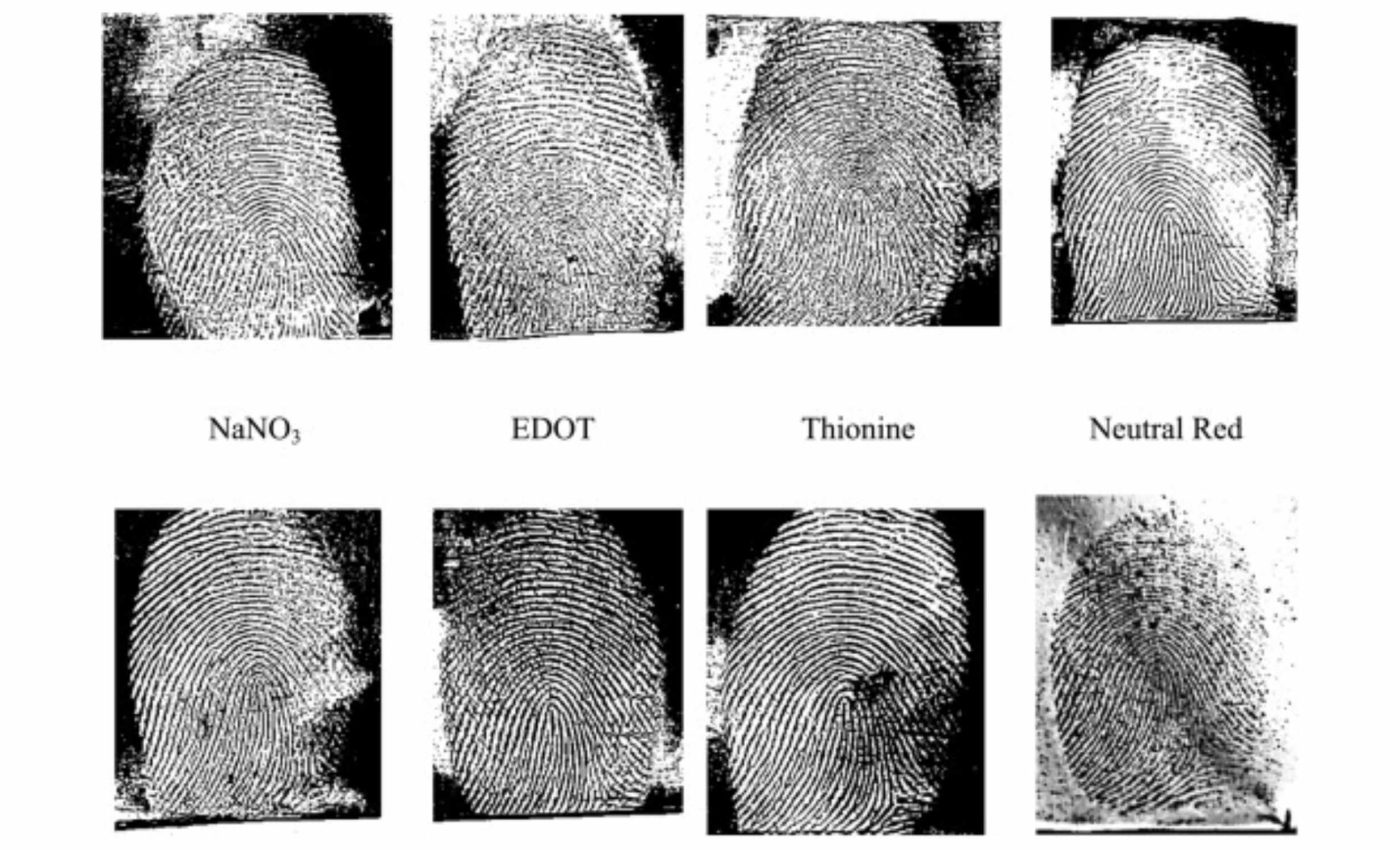

In controlled experiments, the study reported grade 3, level 3 detail on brass after up to 16 months of room-temperature aging and after heating to 700°C, often within about 2 minutes.

The method recovered fine third level features, including pores along ridges, on brass sheets and on cartridge cases. Those are the sorts of details that strengthen an identification when a clear match is needed.

The team also showed that short, gentle runs at low voltage preserved the surface while still revealing ridge paths. That balance matters because overcoating or roughening can hide the very details investigators need.

On curved cartridge cases, the researchers adapted their setup to account for smudging and uneven distances to the counter electrode. Even with that challenge, they reached what examiners call grade 3 quality on multiple trials.

More clues from metal

Today, a shell casing often leads back to a particular gun by its toolmarks. Being able to see fingerprint friction ridge detail on the same bullet casing could point to the last person who loaded or handled it.

Because materials were non-toxic and the energy requirement was low, the process fits the trend toward safer, greener forensic labs. It could also be adapted to compact equipment, which is useful for crowded labs with heavy caseloads.

The chemistry does not chew up the evidence. That means examiners can try other accepted techniques afterward if needed, without losing the sample to a destructive test.

If validated further, the approach could extend beyond bullet casings to other metal evidence. Knives, coins, and other handled objects share the same need for contrast on smooth, tough surfaces.

Next phase for recovering fingerprints

By design, this proof of concept sits at Phase 1, which is the pilot stage that demonstrates feasibility under controlled conditions, consistent with IFRG guidelines.

The next steps include optimization, comparisons against standard workflows, and larger, blinded studies.

Real-world firing introduces messy variables. Skin chemistry varies a lot by person and activity, and gases, soot, and motion can scramble the trace before it ever cools.

Investigators also work with mixed or partial marks, not textbook examples. Any new method must still help a trained examiner decide if a print is suitable for identification.

The team’s early results are promising, and the physics makes sense for metals like brass. Now the challenge is to show robust performance across donors, storage conditions, and ammunition types.

Lessons from bullet fingerprints

The term grade 3 describes high-clarity ridges with many usable features. Level 3 refers to very fine detail like pores and edge shapes that can support a strong conclusion.

Electrochemistry is not magic. It is a controlled way to move electrons so a material organizes itself where the fingerprint did not protect the metal.

This is careful work. A few tenths of a volt, and a minute or two of time can be the difference between a clean ridge map and muddy staining.

Small details add up. The researchers tuned charge passed, the mix of monomers, and the geometry of their three-electrode cells to reach that clarity.

The study is published in Forensic Chemistry.

—–

Like what you read? Subscribe to our newsletter for engaging articles, exclusive content, and the latest updates.

Check us out on EarthSnap, a free app brought to you by Eric Ralls and Earth.com.

—–