Cork converted into graphene using a laser to create toxin sensors

Brazilian researchers built a sensor from cork that uses a laser to spot sodium nitrite in common drinks. It can detect amounts as low as around 1 milligram per liter, which is about one fifth of the U.S. allowable standard.

The team at the Federal University of São Carlos (UFSC) in São Paulo turned thin cork pieces into conductive carbon and then measured tiny electrical signals to flag nitrite. The approach aims for quick screening of mineral water, orange juice, and wine.

Why a nitrite sensor is needed

The work was led by Bruno Campos Janegitz, head of the Laboratory of Sensors, Nanomedicine, and Nanostructured Materials. His research focuses on electrochemical sensors for food safety, and low cost materials.

Sodium nitrite can react with amines to form nitrosamines, chemicals that can cause cancer in animals and people. Several nitrosamines are recognized as reasonably anticipated human carcinogens.

“This risk motivated us to develop a simple, fast, and accessible way to detect the compound and ensure the quality and safety of liquid consumption,” said Janegitz.

Food makers use nitrite to preserve meats and to keep cured products a stable pink color, but beverages are not supposed to rely on nitrite for that purpose.

From cork to graphene

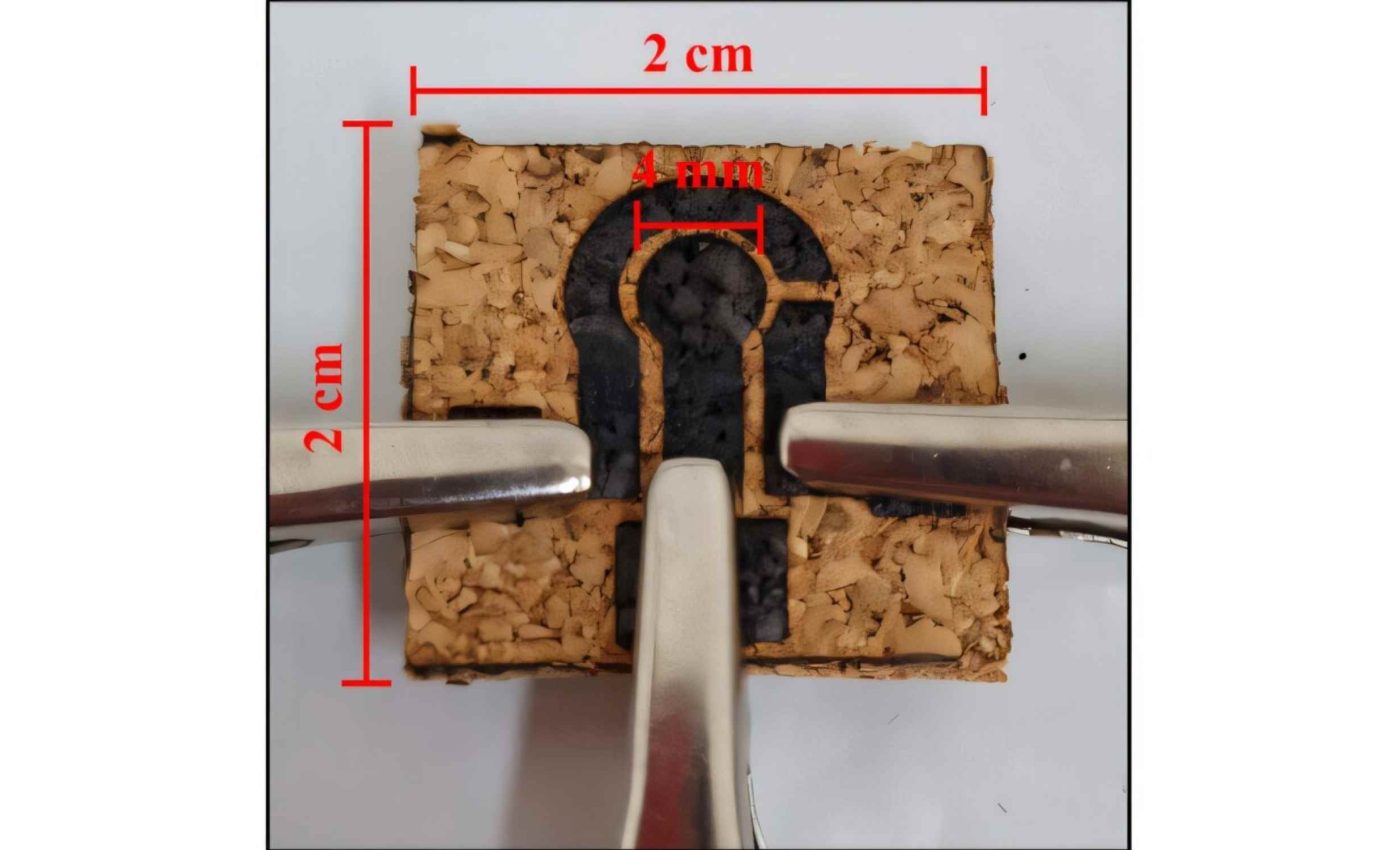

The nitrite sensor starts with cork, which the lab treats with a laser to create laser-induced graphene, a carbon material described in a study as a single layer of atoms arranged in a hexagonal lattice.

Graphene is remarkably strong, flexible, and an excellent conductor of electricity, allowing electrons to move through it with minimal resistance.

In this process, the laser’s heat converts the cork’s surface carbon into that same, highly conductive form. As a result, fine pathways that act like microscopic circuits are etched across the material.

“This process is sustainable, doesn’t require toxic reagents, and results in a highly conductive material, which is essential because nitrite undergoes well-known electrochemical oxidation,” explained Janegitz.

The team then applies a waterproof spray so that liquid does not soak into the cork and blur the signal. Finally, a thin nail polish band marks the active region that will touch the sample.

To stabilize the surface, the pieces are warmed in an oven at 104 degrees Fahrenheit (40 degrees Celsius) for 30 minutes. That step improves the carbon structure and consistency from test to test.

How the nitrite sensor performs

In tests on water, orange juice, and wine, the team reported a strong, stable response. The sensor showed a linear range from 300 to 1000 micromoles per liter and a limit of detection of 14.4 micromoles per liter.

That detection limit is roughly 1 milligram per liter as sodium nitrite. The number sits well below what routine water systems are allowed to deliver.

The device’s accuracy on spiked drinks ranged from 86.1 percent to 110.8 percent. The wide spread reflects how real beverages can shift readings.

The readout relies on electrochemical oxidation, an electron loss reaction that is tracked as current, which rises when nitrite is present. The more current, the higher the nitrite level.

What the measurements mean

For tap water safety, the U.S. cap for nitrite is 1 milligram per liter when counted as nitrogen, which equals about 5 milligrams per liter as sodium nitrite. The sensor’s threshold sits well below that, which is useful for early warning.

For juice and wine, the main interest is quality control. Producers and inspectors want a quick check so they can run without a full lab.

The build also keeps costs in mind. Cork is light, cheap, and renewable, and lasers can mark many pieces in one batch.

From lab bench toward the field

Today the device is at the validation stage with tests of accuracy being made outside ideal lab settings. The group is refining the patterning and the protective coating so the readout stays steady across different drinks.

The prototype uses a small salt solution as the electrolyte – a liquid that carries charge between electrodes – to make measurements reliable. Sample prep remains simple, which helps outside a central lab.

As with any fresh tool, matrix effects – sample ingredients that alter signals – can cause bias or noise. The recovery testing on wine and orange juice begins to address that concern.

If handheld electronics are added, a user could place a drop on the treated cork, wait briefly, and read a number on a small screen. That makes spot checks possible at bottling lines or tasting rooms.

Lessons from nitrate sensors

Cork has a honeycomb-like structure that tolerates heat and builds porous carbon when hit with a laser. That porosity increases the surface area that touches nitrite during measurement.

The laser creates clean patterns without chemical waste. It also avoids expensive microfabrication, which keeps the platform accessible.

Graphene on cork provides a sturdy, flexible surface for repeated use. The waterproof layer extends life by blocking swelling and staining.

Future studies will test shelf life, cleaning cycles, and performance after repeated runs. The team will also probe cross-reactivity with common juice acids and wine tannins.

A portable reader with battery power would move the sensor beyond the benchtop. Data logging and simple prompts could help non-specialists use it with confidence.

The focus remains the same. Keep the materials simple, keep the signal strong, and keep the measurement rapid.

The study is published in Microchimica Acta.

Image credits: Beatriz Germinare et al.

—–

Like what you read? Subscribe to our newsletter for engaging articles, exclusive content, and the latest updates.

Check us out on EarthSnap, a free app brought to you by Eric Ralls and Earth.com.

—–