World's largest engineering project begins to recreate the Sun's energy on Earth

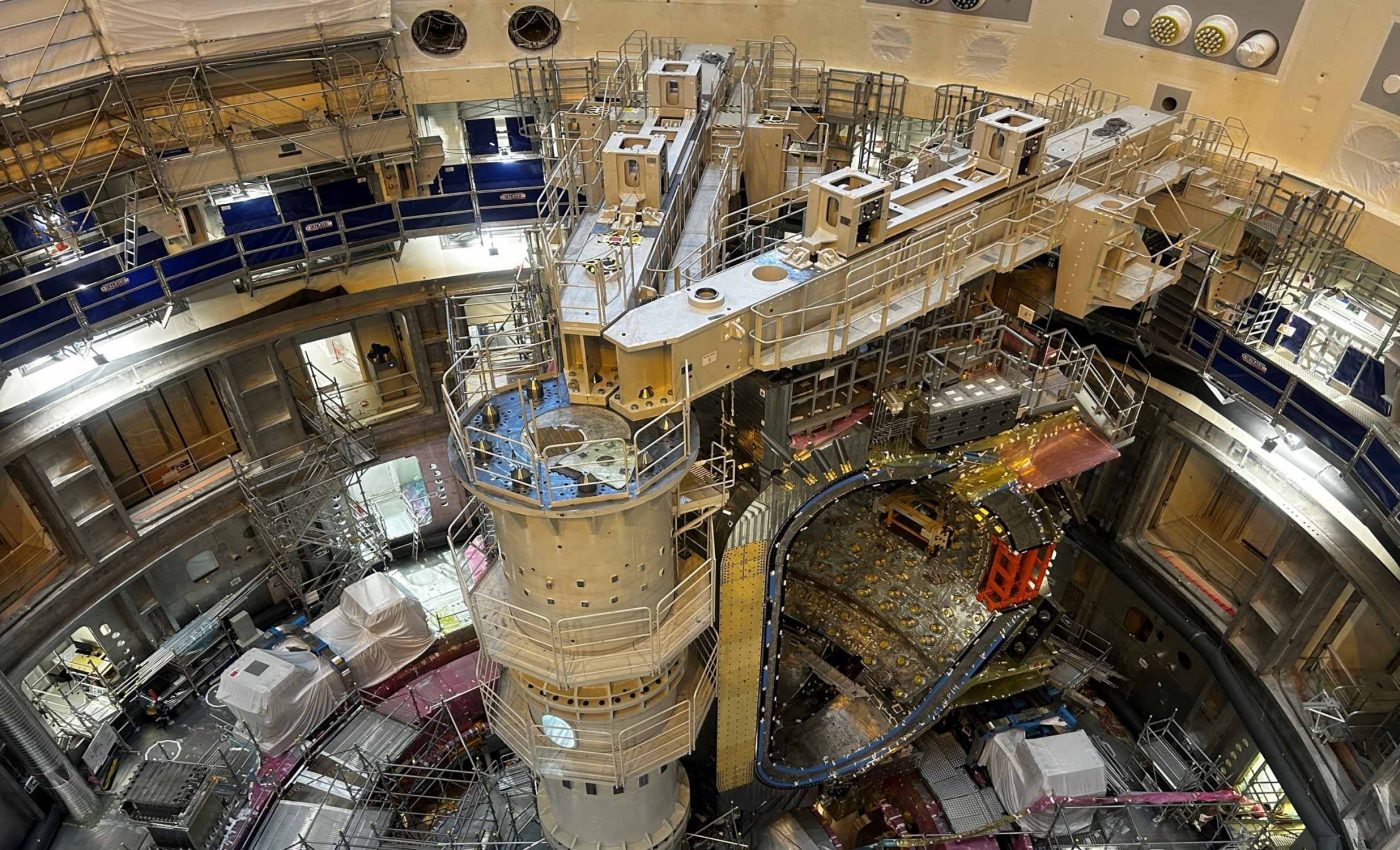

On a plateau in southern France, crews are assembling ITER’s core – a steel chamber about 64 feet wide – to recreate a solar fusion reaction here on Earth.

This is the moment when a decades-long plan to test star-like fusion on Earth shifts from blueprints to hands-on work.

The job is to shape and seal the doughnut where fuel will become a super hot electric gas. That step is delicate because a misaligned weld could undo years of careful building.

Fusion, plasma, and ITER

Inside the chamber, plasma must swirl without touching the walls. If the edge touches steel, the shot ends and sensitive hardware may be at risk.

The work was led by Pietro Barabaschi, Director General of the ITER Organization. His research focuses on integrating complex fusion systems so plasmas can be created and controlled.

The project adopted a new baseline that shifts early operations to hydrogen and deuterium and adds more time for testing. It also front loads safety checks and equipment trials to reduce risk.

The associated study sets milestones through 2036 and 2039. It starts with Start of Research Operations, a structured first experiments phase that runs for 27 months.

Nine giants stitched together

ITER’s vacuum vessel, a sealed double walled steel chamber, spans about 64 feet across and 37 feet tall. Weight comes in around 5,700 tons and will grow when inner shielding is installed.

Europe provides five of the nine sectors, wedge shaped steel slices of the vessel, while Korea supplies four.

A U.S. contractor will weld the sectors into a precise ring once all pieces are clamped in place. The new sequence lowers alignment tolerance, the tiny allowed deviation from ideal geometry, that could spoil plasma control.

Each joint between sectors is a field joint, a long seam that must shrink evenly as welds cool. Robotic tools and patient sequencing are used so heat does not pull the ring out of round.

Same ITER, new fusion plan

The project extends commissioning, checks to prove systems work together, before any fusion fuel is used. It also sets extra tests for some magnet coils at very low temperature.

The core performance target is Q, the fusion power gain factor, of at least 10. That means 50 megawatts of heating will drive 500 megawatts of fusion power in pulses that last several minutes.

Engineers aim to demonstrate full magnetic energy, magnets energized to operating current, before moving to a fuel that breeds its own heat. The staged approach is meant to expose weak links under realistic loads.

ITER is a science facility that will not send electricity to the grid. Its job is to prove that high power, near steady plasmas are possible with deuterium tritium, a hydrogen isotope fuel mix used in fusion.

Why tungsten replaces beryllium

ITER replaced beryllium with tungsten on the first wall, the plasma facing surface that removes heat. The shift cuts waste and aligns ITER with devices planned to run on tungsten.

This change was described as a step that makes the experiment more aligned with the devices planned for the next phase. It was also noted that the decision lowers certain safety concerns associated with beryllium during off normal events.

Tungsten has a very high melting point and resists sputtering, surface atoms knocked off by fast particles. Those traits limit dust and help the wall survive high heat during long pulses.

To keep plasmas clean, operators will use boronization, a thin boron coating that captures stray oxygen atoms. That surface treatment is common in tokamaks and can be renewed between campaigns.

Human scale of a global task

Thirty five nations are in, sharing parts, money, and data. Teams weave interfaces from magnets to cooling water to shape a working whole.

The assembly feels like industrial surgery at continental scale. Specialists in metrology, high precision measurement and alignment work, verify every position before the next lift begins.

Repairs to some delivered hardware slowed work and forced scheduling changes. The payoff is a machine that enters operations more complete, with fewer unknowns parked for later.

Lessons from ITER’s fusion project

Sustained shots at high power would confirm that a large tokamak can tame a hot, dense plasma. It would also validate the control software, sensors, and protection systems that keep a complex plant within bounds.

Data from the start of research operations will sharpen models for disruptions, sudden losses of plasma stability, so engineers can prevent or soften them. It will also fix design targets for components that must manage the next round of heat and neutrons.

Results will flow outward to national labs and to private companies building smaller machines. Success here would mark practical progress, not a finish line, toward fusion systems that can run for hours instead of minutes.

The study is published in Fusion Engineering and Design.

—–

Like what you read? Subscribe to our newsletter for engaging articles, exclusive content, and the latest updates.

Check us out on EarthSnap, a free app brought to you by Eric Ralls and Earth.com.

—–