New 'electronic skin' gives robots the human touch

Roboticists have long dreamed of machines that can pick up an egg without cracking the shell and shake a hand without feeling wooden. Yet most robots still grasp the world through numbers, not nerves.

That gap narrows today thanks to a stretchy gelatin “skin” that cloaks a robotic hand and turns the entire surface into a sensor.

Dr. David Hardman of the University of Cambridge and collaborators at University College London say the material collects touch data while costing only a few dollars to make.

Why robot skin must feel to handle objects safely

A hand without sensation is just a clamp. Robots used in warehouses or orchards often rely on cameras alone and can fumble soft or irregular objects, slowing adoption where safety and speed matter.

Electronic skins that flex like human epidermis have been investigated for years, but many designs tear easily or rely on dozens of fragile sensor tiles.

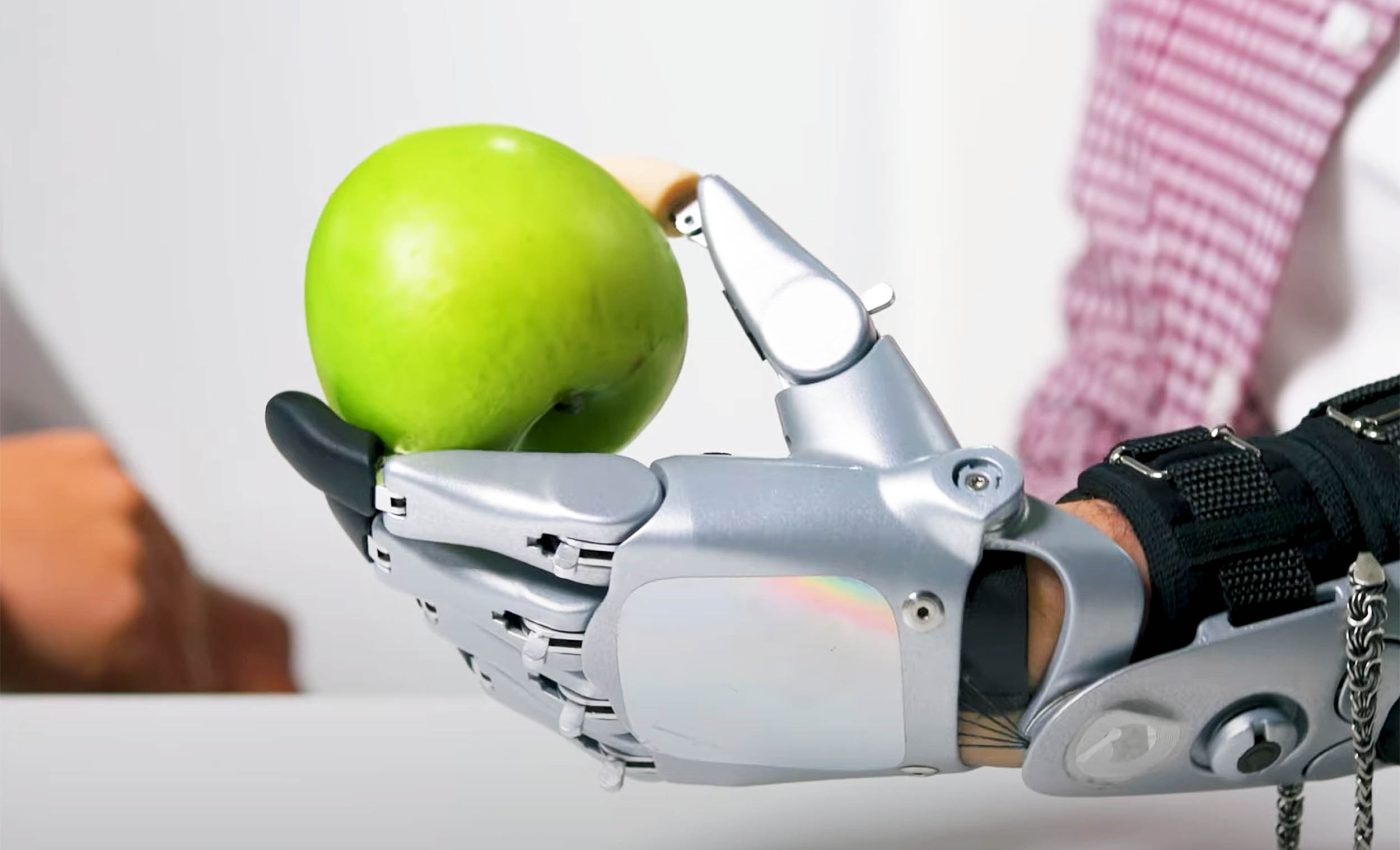

Adding reliable touch also brings better prosthetics. Users of advanced bionic limbs report that even a coarse sense of pressure makes tying shoes easier because they no longer have to watch every movement.

Engineers therefore hunt for materials that feel natural, conduct signals, and survive daily knocks.

Cheap skin gives robots real-time sensing

The Cambridge UCL skin starts with a gelatin‑based hydrogel laced with conductive salt. The team melts the squishy mix, pours it into a glove‑shaped mold, and slips it onto an off‑the‑shelf robotic hand.

Signals are read using electrical impedance tomography (EIT), the same physics behind some medical imaging scanners.

Thirty‑two copper electrodes at the wrist inject tiny currents and measure voltage patterns that ripple through more than 860 000 microscopic pathways in the gel.

“We’re able to squeeze a lot of information from these materials – they can take thousands of measurements very quickly,” said Hardman.

The hydrogel survives bending to 90 degrees and recovers after being cut and rejoined, a property shared with new self‑healing electronic skins reported this year.

What millions of data points reveal

In lab tests the glove sensed a finger tap gentler than the weight of a penny and spotted a 248 °F hot spot in under one second.

Those feats stem from the dense internal network: with a handful of electrodes the researchers harvested 1.7 million data points while the hand handled objects.

Extracting meaning from that torrent called for machine learning. The group trained an algorithm to focus on the pathways that change most under specific stimuli, letting the system tell slicing damage from a multipoint squeeze with 96 percent accuracy.

Similar data‑driven pruning has boosted resolution in earlier EIT skins made for soft robots.

Teaching the hand to interpret touch

Raw impedance plots look like static to the naked eye. After training, the glove could localize a light touch to within a quarter inch, estimate force to within 0.1 pound, and flag cuts long before they severed the gel.

“One type of sensor to detect multiple signals keeps manufacturing simple. We’re not quite at the level where the robotic skin is as good as human skin, but we think it’s better than anything else out there at the moment,” said Dr. Thomas George Thuruthel.

Because the material is transparent to radio waves, the team foresees wireless versions that wrap soft drones or search‑and‑rescue grippers.

A related droplet‑tracking e‑skin published last year shows how single‑layer designs can morph to meet niche tasks such as monitoring water quality.

Real-life use for robotic skin

Automakers already fill dashboards with capacitive touch film; an inexpensive layer that also senses heat and damage could warn drivers before components overheat.

The skin might line collaborative‑robot grippers on factory floors, cutting downtime when humans walk by.

In prosthetics the gelatin makes a comfortable interface and could be infused with vitamins that keep residual limbs healthy.

The material’s low cost (gelatin, salt, and a silicone jacket) also suits disposable medical tools such as soft retractors that alert surgeons if they press too hard.

How it compares to human skin

While the new material isn’t as sensitive as human skin, it replicates some essential properties. It can register a range of stimuli, pressure, heat, sharp contact, from multiple points at once and across a continuous surface.

Human skin still outperforms it in fine resolution, regenerative ability, and biological integration. But the robotic version has an edge in durability, as it won’t scar or lose sensitivity over time.

What’s next for robot skin research

The group aims to toughen the hydrogel against ultraviolet light and dehydration, two weak spots shared by many water‑based gels.

Coating the glove with a breathable elastomer similar to waterproof bandages could triple shelf life without muffling signals.

They also plan to shrink the electronics so a battery and radio fit in a fingertip. If that happens, the age‑old handshake between human and machine may finally feel familiar on both sides.

The study is published in Science Robotics.

—–

Like what you read? Subscribe to our newsletter for engaging articles, exclusive content, and the latest updates.

Check us out on EarthSnap, a free app brought to you by Eric Ralls and Earth.com.

—–