New type of cutting-edge renewable energy launches first project in the U.S.

Waves carry concentrated energy. Wind transfers momentum to the ocean’s surface, and that motion travels as rolling swells that continue long after a gust dies down.

Unlike solar energy and sunlight, which fades at sundown, and wind energy, which shifts from hour to hour, waves can persist through the night. That steady character makes wave power a useful partner for other clean energy sources.

Electricity systems need balance. When one source eases off, another should pick up the slack.

Wave energy offers that kind of support. It can smooth the bumps caused by clouds over solar farms and lulls in local winds. The appeal is clear: add another steady hand to the grid without burning fuel.

How wave energy machines work

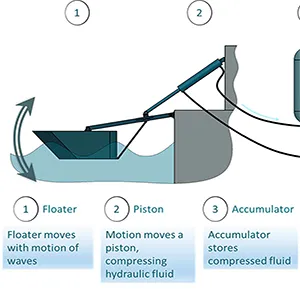

The core hardware uses floaters that rise and fall with passing waves. Each floater links to a piston in a hydraulic circuit. When a wave lifts a floater, the piston pressurizes biodegradable hydraulic fluid inside a closed loop.

Pressurized fluid runs through pipes to onshore equipment, spins a hydraulic motor, and turns a generator that produces electricity.

When the wave passes, the fluid returns to its tank and waits for the next cycle. Only the floaters touch the water; pumps, motors, the generator, and control systems sit in standard containers on the pier.

Eco Wave Power in the U.S.

After years of offshore prototypes around the world, a company called Eco Wave Power brought this approach to a working U.S. harbor. The pilot sits at a blue-economy campus inside the Port of Los Angeles.

The company calls this the first onshore wave energy installation in the United States. The purpose is clear: show the technology in a busy port, record real-world performance, and gather lessons for future, higher-energy sites.

This site does not aim to power the city. It functions as a proving ground. Engineers test how floaters attach to existing structures, how the control software responds to changing seas, and how components hold up during both calm periods and rough days.

Components in the water

Keeping power-conversion equipment onshore improves access. Crews can reach pumps, valves, and generators with ordinary tools. They can swap parts without boats or divers.

With fewer components submerged, there is less corrosion and fewer snag points for debris. Maintenance tasks become quicker and cheaper, and uptime improves.

This layout also avoids long high-voltage cables on the seafloor. Shorter cable runs reduce losses and simplify permitting.

Using existing piers, breakwaters, and seawalls cuts construction time and cost because the project builds on infrastructure already in place.

Floaters and pressure cycles

The wave climate inside a protected port is usually mild. Day to day, the pilot focuses on education and live demonstrations.

When waves have enough energy, visitors can watch the floaters move and the onshore equipment produce power.

When the water is calm, staff can simulate the pressure cycle so people still see the system run and learn the steps of energy conversion.

The team plans a two-year run with tours, trials of different mounting methods – such as clamping to pier piles – and systematic environmental observations. Those records will guide designs for grid-connected locations with stronger waves.

Permitting and ecological footprint

Regulators treated the installation as a low-impact, temporary demonstration.

A compact array of floaters connects to an existing wharf, and the power-conversion equipment sits in two standard shipping containers onshore.

The project avoids heavy marine construction and commits to removal or relocation when testing ends. That choice keeps the footprint small and lets engineers adapt quickly as data arrives.

Environmental impact

Design choices in the pilot aim to limit marine impact. The hydraulic loop remains sealed, so the fluid does not enter the ocean. Because the hardware sits onshore, the project avoids placing large anchors on the seafloor.

No energy project is impact-free, but this approach reduces exposure compared with devices that must survive far offshore year-round.

The site also tracks environmental conditions during operations. Observations related to marine life, debris, and noise help refine future designs.

That feedback will shape how and where larger systems attach to structures and how they operate during storms or maintenance windows.

Wave energy physics

The conversion chain follows the physics you learn in class. A wave carries kinetic and potential energy. The floater intercepts that energy and does work on a piston.

The piston increases fluid pressure, which stores energy. The pressurized fluid turns a motor, which spins a generator to produce electricity.

Each step loses a bit to friction and heat. Engineers cut those losses with tight seals, smooth hydraulics, efficient motors, and smart control algorithms.

Keeping generators and delicate components onshore helps preserve efficiency by reducing corrosion and wear.

Control systems matter as much as the mechanics. The control system decides when to engage floaters, how to tune pressure for the next wave, and when to lift modules out of the water.

Good control boosts power capture during everyday swells and protects equipment during rare, punishing events.

Waves combined with solar and wind

Energy diversity helps the grid. Solar peaks around midday and tapers in the evening. Wind can swing from breezy to still within hours.

Used alongside solar and wind, wave energy can support evening demand and reduce the need for fast-ramping fossil plants.

Colocation is also easier when most equipment sits on land. Ports and coastal towns already host transmission lines and maintenance crews.

Adding wave modules along existing structures can layer clean generation onto familiar working sites without large new footprints offshore.

What success looks like

This pilot sets out to learn fast, not to chase megawatt headlines. Success means dependable operations, clean data, and clear procedures for installation, maintenance, and safety.

It means proof that floaters can attach securely to common port structures and that onshore equipment runs with steady efficiency.

It also means a real-world view of costs – parts, labor, and downtime – that informs the next round of design.

If the data support the approach, the next step moves to higher-energy coastlines with direct grid connections. Longer breakwaters could host strings of floaters.

Onshore containers would scale to match. Smart controls would keep modules safe during storms and ready for power when seas return to normal.

With careful siting and steady improvements, many small units could add up to meaningful clean electricity.

Wave energy’s future in the U.S.

Wave energy will not replace every other source. It does not need to. It needs to do its part – reliably, safely, and at a fair cost.

By mounting floaters on existing structures and keeping sensitive machinery on land, this approach tackles the practical hurdles that slowed earlier offshore attempts. A busy U.S. port now provides the stage to test it.

The lessons from this compact, temporary setup will steer the next build, and the one after that, until the technology proves where it fits best in the energy mix.

—–

Like what you read? Subscribe to our newsletter for engaging articles, exclusive content, and the latest updates.

Check us out on EarthSnap, a free app brought to you by Eric Ralls and Earth.com.

—–