Soft robots called 'metabots' change shape on demand with tiny signals

Thin polymer sheets can now pop into many stable shapes and move without motors. A four-sheet setup forms 256 distinct and highly adaptable metabots, all controlled remotely by fields or voltages.

The project was directed by Jie Yin at North Carolina State University (NCSU), within the Department of Mechanical and Aerospace Engineering.

Yin’s team demonstrated how simple films can turn a flat sheet into a crawler, a jumper, or a gripper, all in one platform.

How the robot forms shapes

The devices start as perforated polymer sheets with thin surface films that respond to electric or magnetic fields, letting the sheet snap between shapes on command.

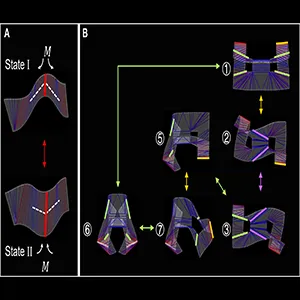

A single unit can reach 20 stable forms, while four connected units achieve 256 highly adaptable and maneuverable metabots.

“By connecting multiple sheets, we create structures that lie flat initially, but can then bend and fold themselves into a wide variety of stable configurations,” said Caizhi Zhou, the first author of the study.

“These films serve as actuators, allowing us to change the shape of the sheet remotely,” said Yin. With just a small signal, the flat sheet can twist, bend, or even crawl across a surface.

The team integrated piezoelectric and magnetic films so the sheets can crawl, hop, turn, and grip objects without onboard motors or gears. The robots switch gaits by changing voltage or field direction rather than swapping parts.

Why microbot shapes stay stable

The key is multistability, the ability to rest in several stable shapes without constant power, which stores elastic energy that the sheet can release quickly. Each switch crosses an energy barrier, so the metabot locks in place until a command pushes it past that threshold.

The sheets use developable surfaces, thin shells that bend without stretching, a geometry that raises the number of distinct shapes. When the team bonds the edges of a cutout, they preload elastic energy that later drives fast snapping between states.

The design avoids rigid hinges by using virtual creases. These are bending lines that form where the shell concentrates curvature, a term for how sharply a surface bends in one direction.

Folding different virtual creases makes new shapes available without adding parts or thickness.

Because the shell is thin, control signals need only nudge the sheet across each barrier. That keeps power low and avoids heavy batteries, which is a common limiter in soft robots.

Why multistability matters

Soft machines often struggle to both adapt shape and hold it without power. Multistability delivers shape memory, which lets a robot keep a pose while the power source idles.

It also allows fast actions when stored energy releases at once. That snap can drive a jump or a quick grasp with limited input, improving efficiency compared with slow, continuously driven actuators.

The approach differs from mechanism-heavy origami devices that require many parts and tight tolerances. It also differs from gels or elastomers that need heat or light and may relax slowly after each cycle.

Here, thin films provide the trigger, and the shell provides the force by releasing stored strain. That split lets the team keep the metabot structure simple while still allowing significant agility.

How shapes drive the metabots

The sheets support several locomotion modes on demand. Under a magnetic field, the structure can curl, store energy, and then leap forward when the field changes.

Change the shape and the same sheet begins to crawl using stick slip footfalls, which soft robotics studies show can be efficient for small, untethered machines.

Adding piezoelectric films – materials that move when voltage is applied – gives another way to steer and turn. The sheet can rotate in place by creating small vibrations at specific frequencies that change friction at the feet.

Because the sheets begin flat, several can be connected to form networks that morph together. That gives a way to scale without adding heavy joints, which often limit soft robot speed and endurance.

Metabots for multiple applications

Metabot grippers built from these sheets can close around fragile items without squeezing hard, since the shell envelops rather than pinches. Locking without power protects the hold while the system moves the payload or repositions its base.

The same body can change into a low-profile crawler to slip through a narrow gap, then switch into a jumper to clear a ledge on the other side. That kind of on demand shape change widens the range of tasks a single metabot can handle.

The design also keeps costs lower by using commodity films and thin polymer stock. Precut patterns and simple bonding steps do most of the work, so fabrication time does not spike when you need many units.

Open questions remain about precise control across dozens of states. Smarter controllers and onboard sensing will improve reliability as robots move from lab floors to cluttered settings.

What comes next

The authors describe this as early stage work aimed at proving the concept across several tasks. Some abilities, like fast state switching under remote fields, still require tuning so the metabot picks the right path through its energy landscape.

Future versions may break symmetry to unlock new shapes and motions. Integrating lightweight sensing and simple feedback could help the sheet know which state it occupies and when to snap to the next.

The approach should generalize to other thin polymer systems and other films. Magnetic and electrical control are natural fits, but light or heat control could slot in once materials and timing are optimized.

If those pieces come together, a flat pack of sheets could unfold into many tools, each shape ready for a specific job. The modularity here sits in the physics rather than in a box of spare parts.

The study is published in the journal Science Advances.

—–

Like what you read? Subscribe to our newsletter for engaging articles, exclusive content, and the latest updates.

Check us out on EarthSnap, a free app brought to you by Eric Ralls and Earth.com.

—–