Scientists create 'super wood' from gene-edited trees and claim it will change everything

Wood looks simple, but it’s a tricky material. Inside every tree are long cellulose fibers, helper sugars called hemicellulose, and a stiff, brown binder known as lignin.

That mix lets trees grow tall and stay standing through wind and weather. It also makes wood tough to reshape into high-performance beams and panels.

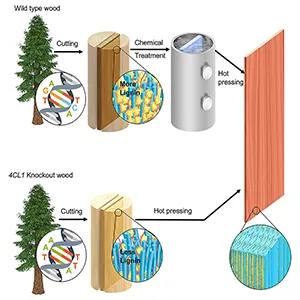

Factories usually force wood into shape with chemicals and heat. They strip out some lignin first, then compress what remains into a dense, strong material.

That step consumes energy, costs money, and generates waste. A team of researchers set out to avoid it.

Engineered wood and lignin

Lignin is great for trees and a challenge for manufacturers. It’s the glue that stiffens cell walls and blocks pests. It resists many industrial treatments.

Take out some lignin and you can pack cellulose fibers closer, which boosts strength. The usual methods require harsh chemicals and high temperatures.

Engineered wood has become a cleaner alternative to steel and concrete in many projects. It’s lighter and can carry serious loads when densified.

To keep that promise, the industry needs cleaner steps from the forest to the factory floor.

Genetics and wood engineering

Researchers at the University of Maryland genetically modified poplar trees to produce high-performance structural wood with fewer chemicals and less energy-intensive processing.

“We are very excited to demonstrate an innovative approach that combines genetic engineering and wood engineering, to sustainably sequester and store carbon in a resilient super wood form,” explained Yiping Qi, a professor in the Department of Plant Science and Landscape Architecture (PSLA) at the University of Maryland.

Instead of modifying wood after the tree grows, the team asked a simple question: could the tree grow wood that’s easier to densify from the start?

They chose poplar, a fast-growing research workhorse that also shows up in real products. Using precise gene editing, they adjusted the tree’s lignin pathway without undermining growth.

They targeted one gene – 4CL1 – within the pathway cells use to make lignin. By switching off 4CL1, the trees produced slightly less lignin, but maintained normal development under controlled conditions.

That small change opened a new option in the factory: skipping the chemical delignification step.

How the gene edit works

The tool was base editing, a form of CRISPR that swaps one DNA letter for another at a chosen spot. It doesn’t slice the genome; it rewrites a letter with precision.

In this case, the edit focused on 4CL1 while minimizing changes elsewhere in the genome.

With the wood in hand, the team soaked it in water and then applied heat and pressure to densify it.

When cellulose fibers line up and move closer together, mechanical strength climbs. The process relies less on solvents and more on physical compaction.

Putting it to the test

The densified wood from the edited poplars reached strength levels comparable to those of panels made with conventional chemical treatments.

The researchers measured lignin levels approximately one-eighth lower than in unedited controls. Growth remained healthy in greenhouse tests, which matters because factory gains aren’t worth much if the tree can’t thrive.

Skipping the chemical bath meant fewer inputs and less waste while still yielding structural-grade material.

The balance was key: reduce lignin just enough to ease processing, not so much that the tree loses toughness in the wild.

CO2 and engineered wood

Buildings are a major source of global carbon emissions, driven by materials like steel and concrete.

Engineered wood can help by replacing part of that footprint with lighter structural components that store carbon for decades. Cleaner processing tightens the loop further, cutting energy use and reducing waste streams.

“Carbon sequestration is critical in our fight against climate change, and such engineered wood may find many uses in the future bioeconomy,” Qi added.

If mills can avoid harsh solvents and still press wood into high-strength beams and panels, the path to lower-carbon construction gets wider.

The approach starts upstream in the forest, not just on the factory line. It tunes the raw material so it cooperates when densified.

Next steps underway

Greenhouse results look good, but forests are tougher proving grounds. Wind, pests, and seasons test wood in ways a lab cannot.

Longer field trials will show whether reduced-lignin trees keep their strength and resilience outdoors. Another step is to try similar edits in pine, spruce, or eucalyptus, which dominate many timber markets.

Policy will shape the path. Base-edited trees do not carry added foreign genes; they contain single-letter changes to DNA already present.

Many regulators treat that differently from classic GMOs, but rules vary by country. Because forestry spans long life cycles and open landscapes, regulators will likely require careful, staged reviews before any commercial rollout.

“Super wood” and Earth’s future

This study shows that small genetic changes can simplify manufacturing while maintaining performance. The edit doesn’t erase lignin; it tunes it.

The result is densified “super wood” that matches the strength of chemically treated material while avoiding the delignification step.

This is a careful blend of biology and materials science aimed at a practical target: strong, reliable wood that stores carbon and reduces the mess of production.

If future field tests and policy steps go well, smarter forests could feed cleaner factories – and sturdier buildings – for years to come.

The full study was published in the journal Matter.

—–

Like what you read? Subscribe to our newsletter for engaging articles, exclusive content, and the latest updates.

Check us out on EarthSnap, a free app brought to you by Eric Ralls and Earth.com.

—–