New 'black metal' solar device generates 15x more energy than current ones

A team of engineers announced a revolutionary new Solar Thermoelectric Generator (STEG) device that turns heat differences into electricity.

The STEG prototype delivered 15 times more power while boosting the temperature split across the device. It also turns that heat gap into electricity using standard thermoelectric modules used in industry.

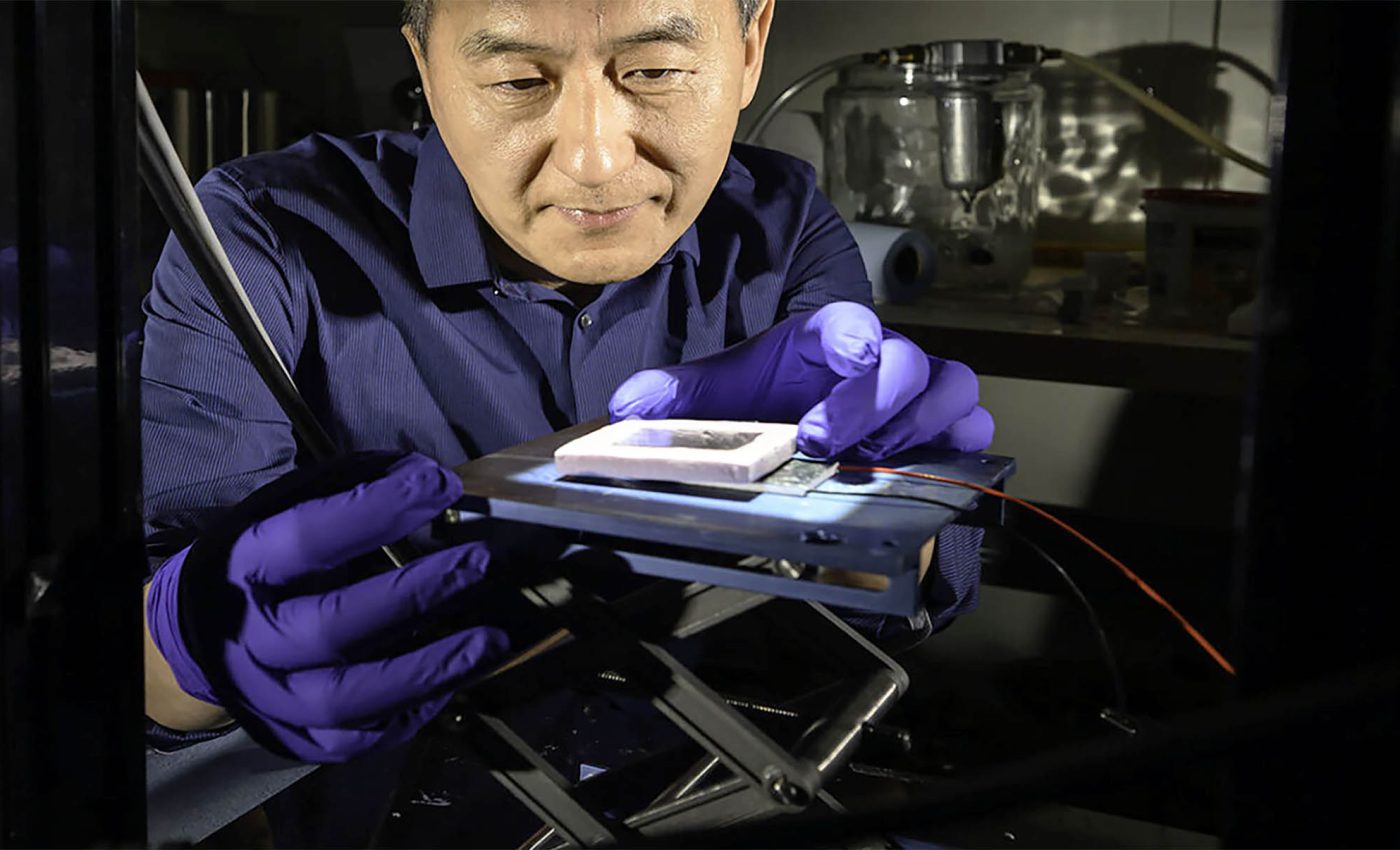

Chunlei Guo of the University of Rochester led the project. His team targeted surfaces rather than the semiconductor itself.

Standard home panels convert about 21 percent of sunlight. STEGs have historically lagged far behind panels, which is why a step change matters for engineers.

“For decades, the research community has been focusing on improving the semiconductor materials used in STEGs,” said Guo. That shift in focus defined the experiment and steered every engineering choice.

That temperature difference triggers the Seebeck effect, a process where heat flowing through a material pushes charge carriers from the hot side to the cold side.

The movement of those charges builds up a measurable voltage, turning simple temperature contrast into usable electrical power.

Light, heat, and STEG

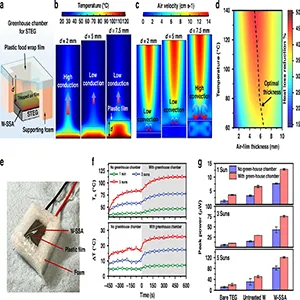

The team leaned on spectral engineering, tuning how a surface absorbs light and emits heat with precision. They also upgraded how each side keeps or sheds heat to strengthen the temperature gap.

On the hot side, they turned tungsten into a highly absorbent black metal with nanoscale patterns. On the cold side, they carved aluminum to move heat away faster through radiation and natural airflow.

The hot surface now absorbs across the solar band while emitting less mid infrared toward the environment. That pairing raises temperature without bleeding away energy as glow that fails to generate power.

The cold surface now favors heat release through radiation and airflow together under ordinary outdoor conditions. Small features make that release stronger for the same footprint and very modest added mass.

How the hot side traps heat

Black tungsten works as a selective absorber, a surface that soaks up sunlight but releases little heat under operating temperatures. That combination boosts temperature without wasting energy as infrared glow that escapes to the air.

The team used a femtosecond laser, an ultrashort pulse tool that sculpts metal at tiny scales with remarkable control. Those pulses etched nanosized textures that trap light and cut radiative losses over a wide band.

They stretched a clear plastic film a little under one quarter inch above the absorber to form a mini greenhouse. The trapped air reduced convection, so the hot side stayed hotter and steadier during illumination.

Avoiding a vacuum chamber kept the setup light and simple for field hardware. The clear film also passed most sunlight, so absorption stayed strong and hot side temperatures rose quickly.

Why the cold side sheds heat faster

Laser textured aluminum raises emissivity, how strongly a surface gives off infrared heat across useful wavelengths. It also increases surface area, which helps natural airflow carry heat away without imposing energy costs.

The micro ridges and grooves were formed directly into thin metal foil with laser scanning. That keeps weight low and makes the cooler efficient for its size even as it improves contact with surrounding air.

Radiative cooling works best when the surface emits across the thermal band that escapes the atmosphere to the sky. The added texture encourages that emission while still allowing air to move alongside the fins.

No fans or pumps were needed, which keeps the system simple and quiet. Passive cooling saves energy and avoids moving parts that wear out under weather and time.

Where STEG could be useful

The team points to the Internet of Things, networks of small sensors that send data for monitoring and control. Self powered nodes could run where cables and frequent battery swaps are a pain for crews.

Wearables and remote field stations could also benefit from a steady trickle of power during daylight. A STEG can harvest sunlight and other heat in the same package during ordinary operation.

Hybrid systems that pair PV cells with thermoelectric stages are under study, as outlined in a recent review. Spectral splitting can send visible light to PV and direct the remaining heat to a STEG for additional output.

Rural clinics and farms need simple power sources that run without attention in tough conditions. A compact unit could keep environmental sensors on and reporting during long stretches without maintenance.

What to watch next

Thermoelectric materials still limit efficiency through a low figure of merit, a simple score that reflects how well they convert heat. Better materials for higher temperatures could unlock more power and durability in long service.

Durability and weather sealing will also matter for outdoor use across seasons. The plastic cover must handle sun, heat, and dust without clouding or warping across repeated cycles.

Manufacturing speed will influence cost because laser texturing takes time over large surface areas. Line scanning, batch tools, or roll to roll methods could boost throughput and cut price per watt.

For now, this technology aims at low power niches rather than rooftop electricity for homes. That focus aligns with sensors, wearables, and other modest loads that already fit ultra efficient designs.

Practical details to consider

Angle to the sun still matters for heat collection. A small tilt adjustment can keep the hot side efficient.

Dust and scratches degrade optical performance over time in outdoor settings. Hard coatings or replaceable films would help retain absorption.

Heat paste and interfaces must stay stable under daily temperature cycling to avoid degradation. Materials that resist drying and cracking will prolong life.

Mounting the cooler in open air improves convection in most climates. Designers can avoid blocked airflow by spacing the fins well away from walls.

The study is published in Light: Science & Applications.

—–

Like what you read? Subscribe to our newsletter for engaging articles, exclusive content, and the latest updates.

Check us out on EarthSnap, a free app brought to you by Eric Ralls and Earth.com.

—–