New parachute design achieves near-perfect, straight descents

A simple plastic disc, cut with a looping pattern, can do something parachutes rarely manage: fall almost perfectly straight. In repeated tests, the thin Mylar disc steadied itself in midair and hit within about three feet of its target from 54 feet up – even in gusty indoor and outdoor conditions.

The work was led by David Mélançon, an assistant professor of mechanical engineering at Polytechnique Montréal in Canada.

His team, working with engineers at École Polytechnique in France, turned a flat sheet into a stable, inverted-bell parachute that drops straight rather than wandering sideways in crosswinds.

Cut makes a parachute fall straight

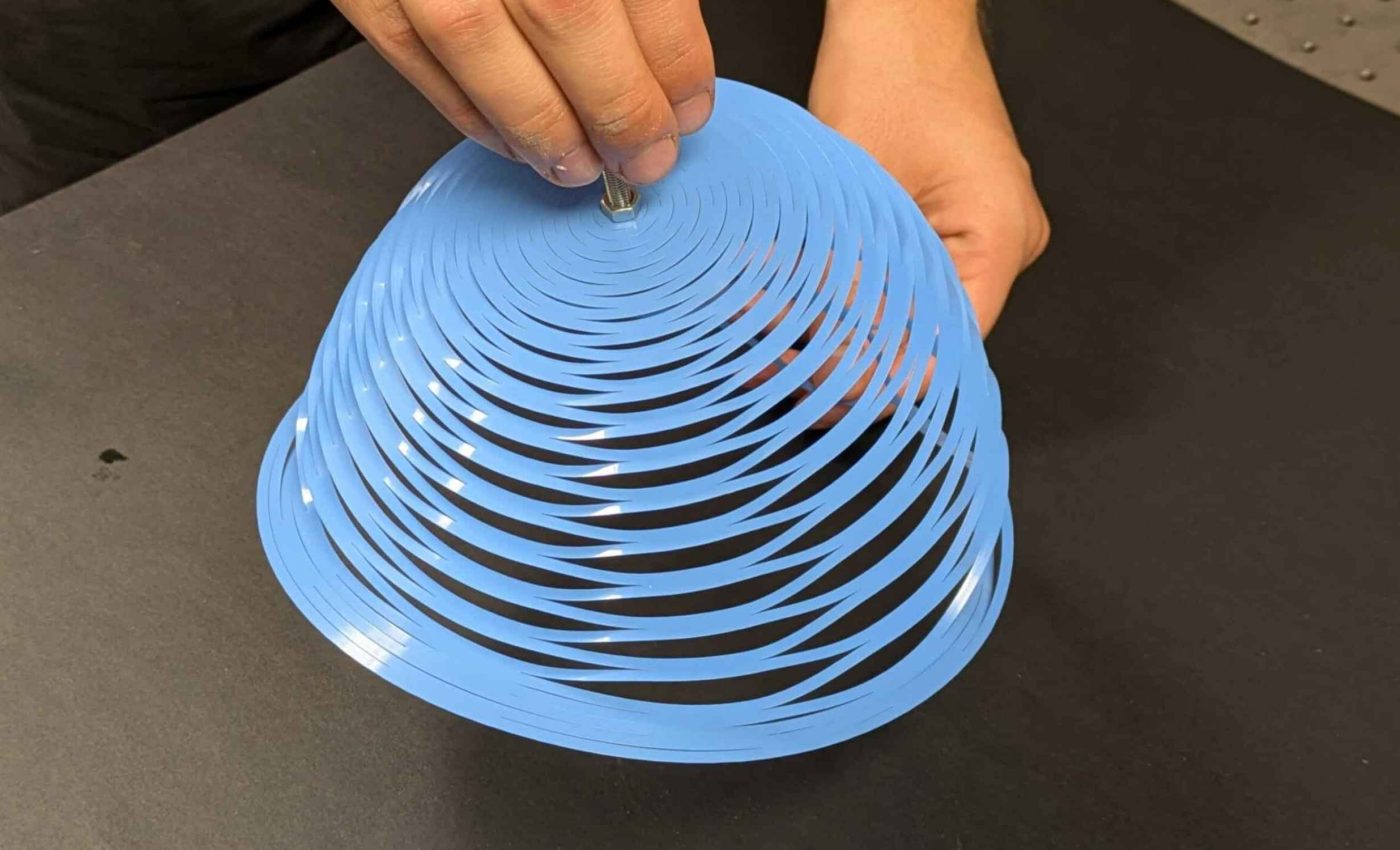

Engineers borrowed kirigami – a Japanese paper cutting art – a method of slicing a sheet to control how it bends and stretches. Instead of sewing fabric and lines, they laser-cut a closed loop pattern into a Mylar disc and hung a small weight from its center.

The disc was made from Mylar, a tough polyester plastic film used in kites and balloons. It keeps its shape well under load and tolerates clean laser cuts without fraying or loose fibers.

That pattern forces the disc to puff into an upside-down bell as air flows by. The shape is stiff in the right direction and flexible where it needs to be, which keeps the descent straight.

What keeps the parachute straight

The slits add porosity. They also add flexibility, so different parts of the disc reorient until the forces balance, calming jitter as the fall begins.

The result is flow-induced reconfiguration, a shape change driven by moving air, which trims drag growth as speed rises. The disc aligns with the air and stops tumbling, so the payload does not swing wildly or shed parts.

Once the motion settles, the system reaches terminal velocity, the steady fall speed when drag equals weight. This trades a little speed for a lot of control, a swap that improves accuracy when wind and release angle vary.

The same behavior showed up from palm-sized samples to half-meter builds. Changes in size did not undo the self centering effect or the clean, vertical path in indoor and outdoor trials.

Proof the design works

In the lab, the researchers compared three Mylar discs, one uncut, one with many concentric slits, and one with the simple closed-loop pattern. Only the third design stabilized instantly and landed within roughly three feet of the target in repeated drops.

They then ran wind tunnel trials and outdoor drops with a drone carrying a water bottle from about 200 feet. The parachute again settled into a steady fall with little sideways drift and no pitching, even when launched off-level.

“It will always realign and then fall straight down,” said Mélançon. That steady, straight path is what gives the design its accuracy.

In a 54-foot indoor test, the team also tried release angles of 0 degrees, 45 degrees, and 90 degrees. The landing spread stayed small, which makes aiming simpler for drops in tight spaces.

The value of accurate parachutes

Most parachutes need sewn fabric, cords, and careful packing. This one is a single thin sheet, cut by laser or a die press, then clipped to a single line, a manufacturing path that lowers costs and makes scaling easier in standard workshops.

Lower drift means fewer lost packages when wind shifts hit mid-drop. For aid groups, that can translate to more food, water, or medicine arriving where people wait, rather than scattered across a field or a riverbank, and fewer risky retrievals.

Because the method is pattern based, production can adapt to different weights without redesigning a whole canopy. It also avoids knots, seams, and tangles that ruin many small drops in rough conditions by adjusting ring spacing or slit count.

The cuts can be stamped by the thousand on rolls of plastic using common tooling. That opens a route to disposable or recyclable parachutes for emergency logistics where recovery is unlikely and to classroom kits that teach physics safely.

Where the design goes next

The team sees a path to slower descents by covering the slits with a soft, stretchy film. That could raise drag without losing the self-aligning behavior, extending use to fragile payloads and sensor packages, including medical swabs.

They also point to ballistic-trajectory, a nearly straight path set by gravity and the initial release, as a feature engineers can tune. With asymmetric cuts, a drop might spiral gently or glide a short distance before settling on the target, which allows steering without motors.

There is room for precision delivery across Earth and beyond. Tests in thin air, like high mountains and Mars analog sites, will demand rugged, simple gear that tolerates cold, dust, and thin air, which is where a cut sheet has an edge.

The current parachutes are meant for small loads and short drops, not people or high-altitude entries. Yet for drones, sensors, and aid packets, the mix of simplicity and accuracy is hard to ignore for missions.

The study is published in Nature.

Image credits: Martin Primeau.

—–

Like what you read? Subscribe to our newsletter for engaging articles, exclusive content, and the latest updates.

Check us out on EarthSnap, a free app brought to you by Eric Ralls and Earth.com.

—–