New tech gives batteries over 12,000 charges without losing power

Electric cars and phones eventually slow to a crawl when the battery loses lithium. A team in Shanghai says a simple add-in can bring that lithium back into play, and one lab cell kept working after nearly 12,000 charge cycles.

The idea is to add a lithium rich salt into a tired battery so it can accept and deliver charge again. If it scales beyond the lab, the approach could keep a lot of packs out of scrap heaps.

How lithium boosts a battery

The work comes from Yue Gao’s group at Fudan University in Shanghai, China. His team trained models to search for a small molecule that would release lithium inside a working cell.

They landed on lithium trifluoromethanesulfinate, a salt that dissolves in the battery’s electrolyte, the liquid that lets charged atoms move between electrodes.

During a controlled first charge, the molecule breaks apart, freeing lithium ions while leftover gases vent safely.

The team calls this an external lithium supply because the added lithium is not built into the battery’s parts. It sidesteps older prelithiation, adding lithium to electrodes before use to offset losses, which can leave residues and complicate manufacturing.

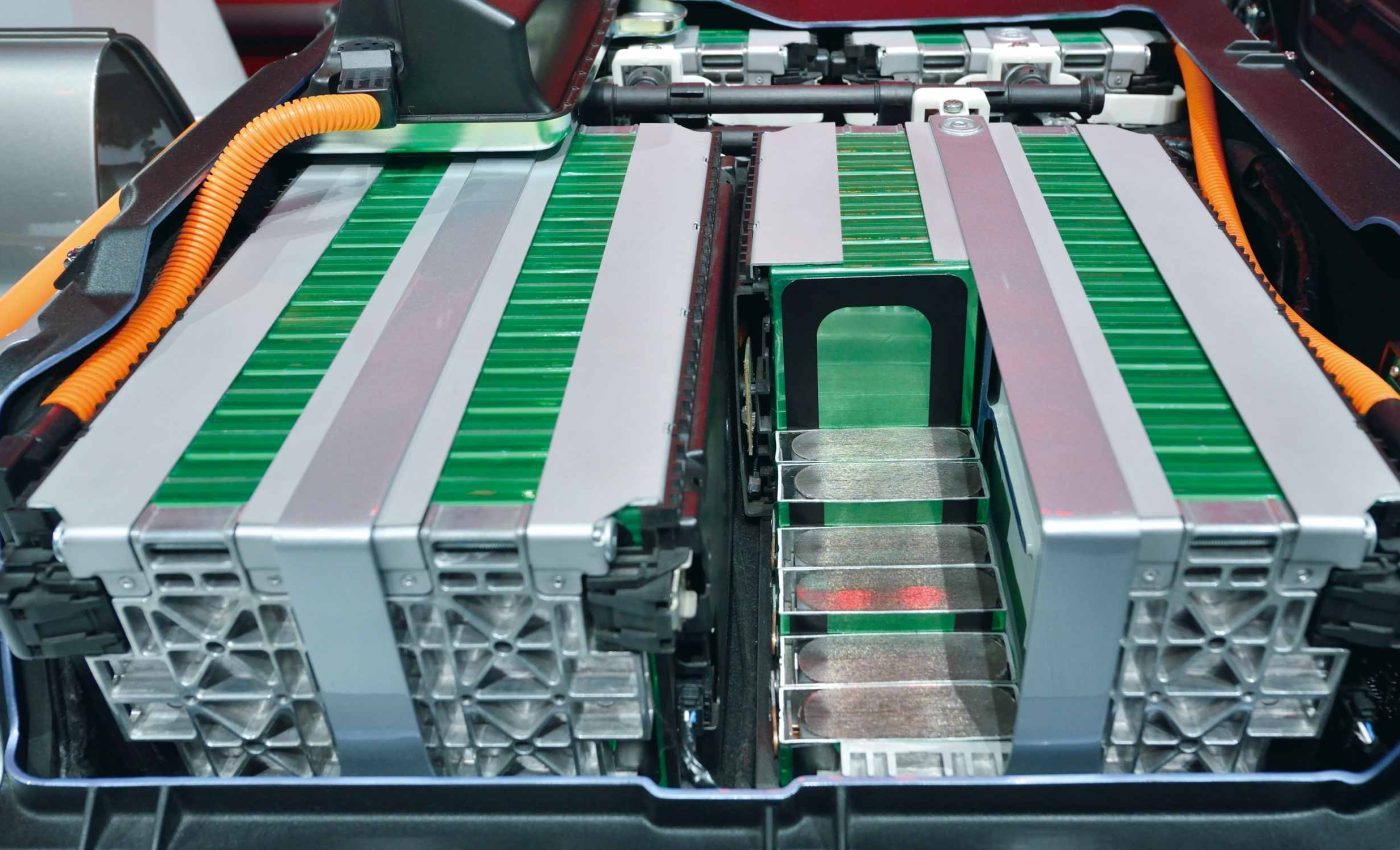

Think of the cell’s positive and negative sides as traffic lanes for lithium. The cathode, the positive side during discharge, and the anode, the negative side during discharge, can both keep their structure while the extra lithium restores the flow.

What the tests showed

In standard tests, the lithium salt delivered a steady charge plateau near 3.8 to 3.9 volts. The cells accepted the new lithium without damaging the internal layers that protect the electrodes.

A commercial type made with lithium iron phosphate, often called LFP, was restored repeatedly. LFP showed near new performance after many refresh steps, and the cells held their voltage behavior with little drift.

The same concept also worked outside LFP. The group demonstrated versions that revived other common chemistries used in vehicles and storage.

The team also explored a pouch format that is common in consumer electronics. An anode-less, having no lithium stored in the anode at the start, test cell ran reliably after being supplied with external lithium, which hints at simpler pack assembly routes.

Why lithium battery boost matters

By 2040, the world could face about 22.6 million tons of spent lithium ion batteries, according to a new report. That is a lot of heavy, complicated hardware that should not end up in landfills.

This year’s end of life battery flow is roughly 990,000 tons. Reusing packs before recycling could trim pressure on raw materials and factories.

Directly topping up lithium could help more than cars. Grid scale batteries sit in one place for years, and even small efficiency gains can add up across thousands of cells.

Keeping old packs in service longer can also reduce the need for intense processing of black mass, shredded mixed battery material recovered for metals. Every battery that avoids that step saves energy and cuts emissions from smelting and leaching.

What could go wrong

Any method that adds chemicals into a sealed system must be proven safe. Batteries heat up when they work hard, so stability across hot and cold conditions needs careful testing.

“If we can give an injection to a sick person to help them recover, why can’t we have a magic potion for drained batteries, too?” said Gao.

Pack design is another hurdle. A modern vehicle pack holds hundreds to thousands of cells, plus electronics and cooling lines that complicate any service step.

There is also the question of compatibility across many chemistries and suppliers. “The team’s work is revolutionary because it provides a new idea to reuse end-of-life batteries,” said Jiangong Zhu of Tongji University in Shanghai.

Battery life and lithium’s future

One advantage of this approach is how it leaves little behind. The salt breaks into gases during a controlled formation charge, and those gases are removed so the cell interior stays clean.

Engineers will look for signs of rising resistance or unwanted deposits over time. High coulombic efficiency, the ratio of charge out to charge in, would signal that most electrons still do useful work during each cycle.

Service logistics matter too. The study describes ways to connect cells to fluid lines so technicians can fill and remove electrolyte, the liquid that lets charged atoms move between electrodes, during maintenance.

LFP shows up in more and more mainstream vehicles because it is robust and avoids pricey metals. If external lithium supply keeps LFP fresh, the same pack could live through more miles and more summers.

Yue Gao and colleagues at Fudan University led the core chemistry and testing. Their models used artificial intelligence to search reaction space faster than trial and error in the lab.

Validation happens when independent teams repeat results. Look for third party reports of LFP cells that keep strong capacity after many refills in long tests.

Real world packs must pass mechanical abuse, thermal runaway, and vibration. Policy and cost will shape adoption. If re-supply in the field costs less than a fresh pack per kilowatt hour, fleets and utilities will pay attention.

What this does not claim to be

The method does not change physics that govern aging, such as growth of films that can slow ion motion. It addresses one core limit, the loss of active lithium, and it leaves other failure modes to conventional fixes.

It is not a license to skip recycling. Every battery will still reach a point where its parts belong in safe processing lines and material recovery.

It is not the end of new cell designs either. Better separators, binders, and electrolytes will continue to push performance forward.

It is not a quick drop in to any pack on the road today. Engineers will need access ports and procedures that fit many sizes, chemistries, and brands.

The study is published in Nature.

—–

Like what you read? Subscribe to our newsletter for engaging articles, exclusive content, and the latest updates.

Check us out on EarthSnap, a free app brought to you by Eric Ralls and Earth.com.

—–