This 3,000-ton magnet could change the future of energy forever

A 3,000‑ton stack of metal and superconducting cable is taking shape in southern France. Engineers say it will cage star‑hot plasma and tip the scales toward commercial fusion power.

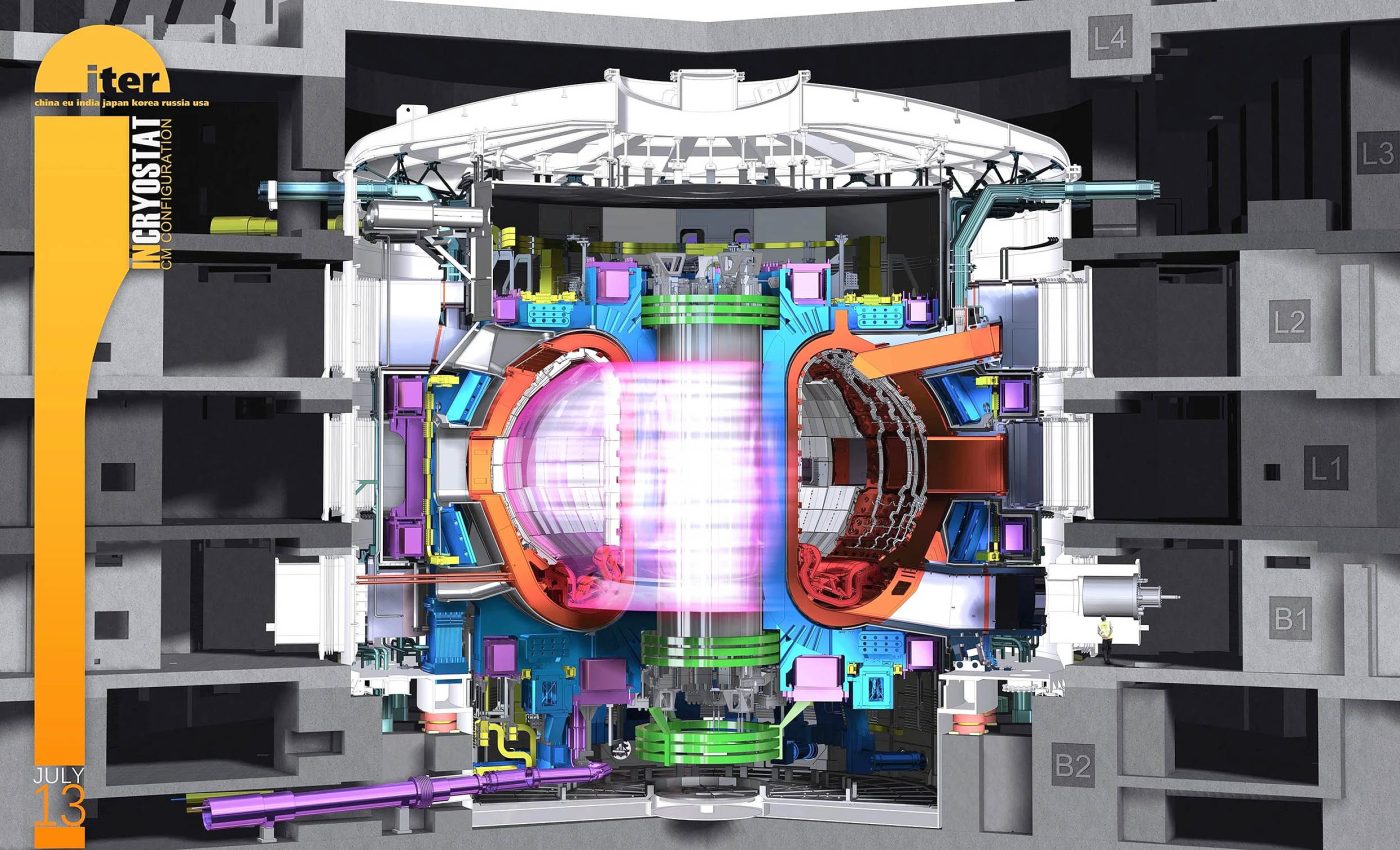

The massive structure, formally called the pulsed superconducting magnet system, sits at the center of ITER’s tokamak reactor.

Karim El Hamdani from the ITER Organization leads the team racing to finish the cold‑test facility before assembly deadlines tighten.

Size matters for ITER fusion energy

Fusion demands magnetic muscle. The central solenoid alone will stand 59 feet tall and weigh 1,000 tons, generating a 13‑tesla field strong enough to hoist an aircraft carrier.

Add six ring‑shaped poloidal magnets and eighteen D‑shaped toroidal coils and the total reaches roughly 3,000 tons, holding plasma currents of 15 million amps.

ITER aims for a ten‑to‑one energy payoff, producing 500 megawatts of fusion heat from 50 megawatts of external power. That target, known as Q ≥ 10, would mark a leap beyond every device built so far.

Each module of the central solenoid took over two years to build and test. The sixth and final module, weighing 110 tons, was fabricated and validated by General Atomics in Poway, California.

Final tests included helium leak checks, insulation integrity, cooldowns to 4.5 Kelvin, and electrical charging to 48,500 amps. Once all modules are stacked in France, they’ll form a column nearly 60 feet tall at the heart of the tokamak.

What makes it tick

Each coil uses miles of niobium‑tin or niobium‑titanium wire cooled to 4 Kelvin, about −452 °F, where superconducting electrons move with zero resistance.

Inside its own cryostat, the new test facility will chill full‑scale coils and push up to 68,000 amps through them before they ever reach the reactor hall.

“We’ve gone from nothing to a design that is essentially finalized. This pace was possible because everybody stayed agile at ITER,” said El Hamdani.

All of ITER’s magnets must operate near absolute zero to achieve superconductivity. This means circulating liquid helium through 18 miles of cryolines to maintain a steady 4.5 Kelvin, or −452 °F.

India built the cryostat, a 98‑foot‑wide stainless steel chamber that houses the entire reactor system. At 3,850 tons, it is the largest high‑vacuum pressure chamber ever constructed for a fusion device.

Testing power before plasma

Engineers have already started validating ITER’s heating systems using a full-scale prototype called MITICA.

Located in Padua, Italy, MITICA recently hit 710 kilovolts across its simulated acceleration stages, exceeding the 700-kilovolt goal set for ITER’s first campaign.

Even without the final beam source installed, MITICA’s electrostatic mock-up allowed teams to identify issues and refine shielding components.

These early insights will help avoid problems during high-voltage neutral beam injection inside the main tokamak.

The window is narrow. Installation crews re‑purposed an old winding shop, upgraded its crane to lift 800‑ton loads, and ordered a 330‑ton cryostat built in parallel.

Factory tests show the power system is 95 percent complete, with quench‑detection software nearly finished.

Horizontal testing demands a custom in‑cryostat feeder to route helium and power. Delivery is expected within weeks. Commissioning of support lines and vacuum pumps begins this month, even before the cryostat arrives on site.

ITER fusion energy and Earth’s future

Validation at −452 °F will shake out sensor glitches, coolant flow limits, and alignment tolerances measured in thousandths of an inch. Every problem solved in the test bay reduces risk when the same hardware slides into the reactor pit.

The magnets must survive pulses lasting eight minutes and forces topping 22‑million pounds. Their success would clear one of the last engineering hurdles between experimental science and grid‑scale fusion plants.

Once stacked, the solenoid, poloidal, and toroidal coils become an electromagnetic cage surrounding fuel no heavier than a handful of hydrogen gas.

Heating systems will raise that fuel to 270 million °F, where atomic nuclei fuse and release torrents of energy.

If ITER meets its power target, it will supply data that private companies can fold into faster, cheaper reactors. Its members already share designs with startups through new tech‑transfer channels launched in 2024.

The magnet story also shows global cooperation still works. Components came from factories in the United States, China, Japan, Korea, Russia, and Europe, all machined to fit together within millimeters.

Engineers on site say the pace has tightened their bond and sharpened methods that future plants will inherit.

Bringing in private partners

In 2024, ITER launched an initiative to share its data and designs with private fusion companies. The goal is to speed up commercial development by offering access to research, documentation, and supply chain knowledge.

A workshop in April 2025 brought together government and industry teams to identify ways to apply ITER’s advances in real-world reactors. These partnerships are expected to lower costs, reduce risk, and shrink the timeline for bringing fusion power to the grid.

—–

Like what you read? Subscribe to our newsletter for engaging articles, exclusive content, and the latest updates.

Check us out on EarthSnap, a free app brought to you by Eric Ralls and Earth.com.

—–