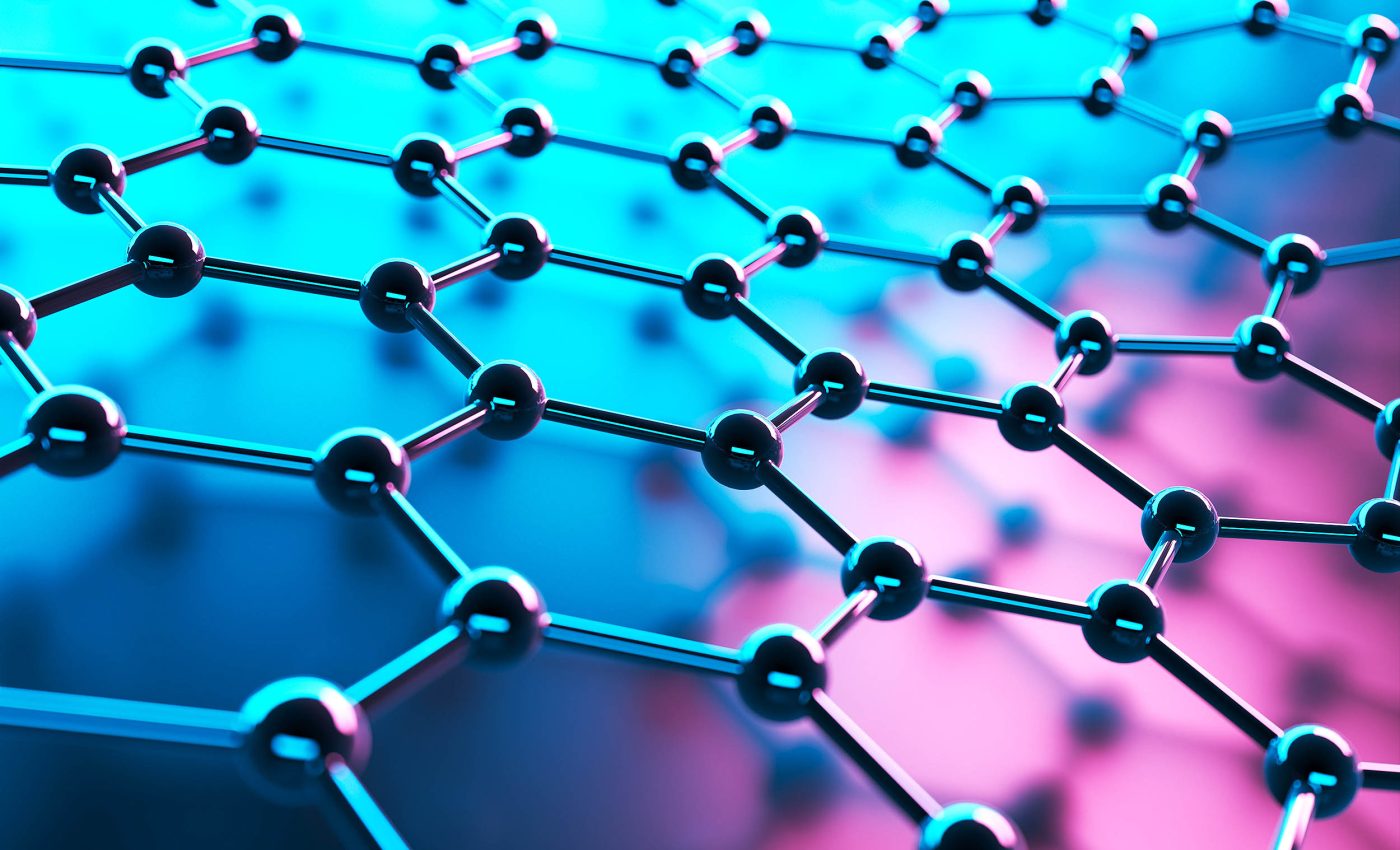

Scientists create a two-dimensional carbon material eight times stronger than graphene

A new carbon material is gaining attention for its incredible resilience, offering hope for stronger and more durable technologies. Rice University scientists report that monolayer amorphous carbon (MAC) is eight times tougher than graphene.

This two-dimensional, single-atom-thick material combines crystalline and disordered regions, creating a unique composite structure.

The material’s unusual combination of structures results in greater toughness.

“This unique design prevents cracks from propagating easily, allowing the material to absorb more energy before breaking,” said graduate student Bongki Shin, first author of the study.

MAC fracture process

Researchers at Rice used in situ tensile testing inside a scanning electron microscope to directly observe how MAC withstands stress.

Cracks in the material were seen to slow, branch, and even stop before breaking the structure apart.

Simulations from Markus Buehler’s group at MIT backed this up at the atomic level. They showed how the interface between ordered and disordered regions raised the energy required to fracture the material.

“This hadn’t been done before because creating and imaging an ultrathin, disordered material at the atomic scale is extremely challenging,” said Yimo Han, assistant professor and a corresponding author.

Professor Jun Lou, also a corresponding author, believes this internal design strategy might apply to other 2D materials as well. The goal is to make them more useful in real-world conditions where brittleness has been a barrier.

Why MAC behaves differently

Molecular dynamics simulations were key to understanding why MAC behaves so differently from other carbon materials.

These models allowed researchers to watch crack behavior down to individual atoms, revealing how amorphous regions interact with stress in unexpected ways.

By adjusting the size and distribution of crystalline domains in the models, scientists saw how small structural tweaks impacted toughness.

This helps guide experimental design and supports the idea that internal disorder can be engineered, not just tolerated.

Graphene is known for being incredibly strong. It resists stretching and compressing better than most materials on Earth. But it’s also brittle. When a crack starts, it tends to shoot through quickly, causing sudden failure.

MAC’s unique advantage

MAC, on the other hand, doesn’t just resist deformation. It handles cracks by forcing them to branch or stall. This increase in fracture energy enhances the material‘s toughness.

It does this without losing stiffness, which means it could be used in the same kinds of devices that currently rely on graphene.

Two-dimensional materials have potential in flexible electronics, sensors, solar panels, and batteries. But their weakness under stress has held them back.

MAC could change that. It might protect sensitive layers in devices that need to bend or stretch without breaking.

MAC is synthesized using laser‑assisted chemical vapor deposition, the same method applied to graphene and hexagonal boron nitride (h‑BN).

This means the process can be scaled up using existing equipment and know-how, which speeds up real-world adoption.

Adapting the design

Professor Lou noted that other 2D materials might benefit from a similar approach. If so, engineers could develop a new family of thin, durable materials with customizable fracture resistance.

So far, testing has focused on how MAC handles tension. Scientists want to understand how it behaves under bending, shear, and long-term stress.

The preliminary studies indicate MAC acts as an insulator with a tunable bandgap, opening up possible applications in electronics and surface coatings.

This combination of toughness and electrical properties could lead to new designs in wearable tech, aerospace electronics, and smart coatings.

Researchers also want to understand how to control the ratio of crystalline to amorphous regions. This balance affects not only toughness but also conductivity and weight.

Controlling this internal structure is difficult at such a small scale. But improvements in high-resolution imaging and synthesis techniques are making it possible.

Why does any of this matter?

This is one of the first clear demonstrations that blending internal structures in 2D materials can make them tougher without adding extra layers.

In the past, materials scientists tried to strengthen 2D materials by stacking reinforcements or applying coatings. But these added thickness and complexity.

Materials like molybdenum disulfide (MoS₂) and hexagonal boron nitride (h‑BN) are also popular in the 2D space, each offering unique electronic or thermal properties.

However, they too suffer from brittleness, making them vulnerable under stress.

MAC’s combination of fracture resistance and structural adaptability puts it in a different category. It doesn’t rely on external reinforcement like multilayer stacking or hybridization, which gives it a design edge for thin, high-performance applications.

Next steps for MAC

The internal approach shown by MAC avoids those drawbacks. It uses structure, not bulk, to achieve results.

It’s a step forward for flexible electronics, especially in harsh or high-performance settings like medical sensors or foldable devices.

With further refinement, MAC could become the standard protective layer for thin devices that need to perform under stress.

The study is published in Matter.

—–

Like what you read? Subscribe to our newsletter for engaging articles, exclusive content, and the latest updates.

Check us out on EarthSnap, a free app brought to you by Eric Ralls and Earth.com.

—–